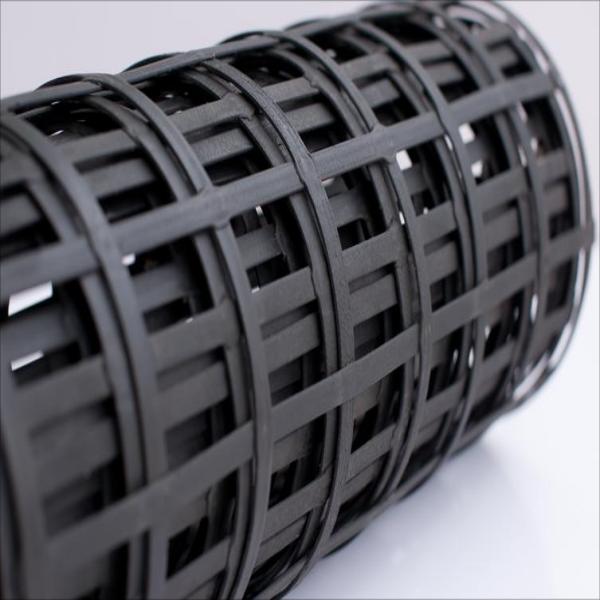

Steel-plastic geogrid

Short Description:

The steel – plastic geogrid takes high – strength steel wires (or other fibers) as the core stress – bearing framework. After special treatment, it is combined with plastics such as polyethylene (PE) or polypropylene (PP) and other additives, and a composite high – strength tensile strip is formed through the extrusion process. The surface of the strip usually has rough embossed patterns. Each single strip is then woven or clamped longitudinally and transversely at a certain spacing, and the joints are welded by a special strengthened bonding and fusion welding technology to finally form the steel – plastic geogrid.

Characteristics and Performance

High strength and low creep: The tensile force is borne by the high - strength steel wires woven longitudinally and transversely. It can produce an extremely high tensile modulus under low - strain conditions. The steel wires of the longitudinal and transverse ribs are woven into a net, and the outer wrapping layer is formed in one - step. The steel wires and the outer wrapping layer work in coordination, and the breaking elongation rate is very low, not more than 3%. The creep of the steel wires, which are the main stress - bearing units, is extremely low.

High friction coefficient: By treating the plastic surface during the production process and pressing out rough patterns, the roughness of the geogrid surface can be enhanced, significantly increasing the friction coefficient between the steel - plastic composite geogrid and the soil, and effectively strengthening the interlocking effect of the geogrid on the soil.

Wide - width, high - efficiency and economical: The width can reach 6m. In engineering applications, it can achieve high - efficiency and economical reinforcement effects, reduce construction laps, improve construction efficiency, and lower construction costs.

Strong corrosion resistance: The use of materials such as high - density polyethylene ensures that it will not be eroded by acid - base and salt solutions, oils at room temperature, nor will it be affected by water dissolution or microbial invasion. At the same time, it can resist aging caused by ultraviolet radiation.

Convenient construction: It is lightweight, easy to carry and lay, and the construction process is simple and fast. It can be used in combination with other geosynthetics.

Application Fields

Road engineering: It is used for the reinforcement of highway and railway subgrades. It can effectively distribute and disperse the load, improve the stability and bearing capacity of the subgrade, extend the service life of the road, reduce subgrade deformation and cracking, reduce deflection, reduce rutting, and delay the occurrence time of cracks.

Water conservancy projects: It can be applied to reservoir dams, flood - control dikes, dams, beach treatment, etc., enhancing the stability of the dams, preventing soil erosion and dam deformation.

Port engineering: In projects such as wharves and revetments, it can improve the bearing capacity of the foundation, resist the scouring and erosion of external forces such as ocean waves, and ensure the safety of port facilities.

Construction engineering: It is used for soft soil foundation reinforcement, retaining walls, slope protection, etc. It can improve the self - bearing capacity of the soil, reduce the earth pressure of the retaining wall, and save project costs.

Other fields: It can also be used in civil engineering such as airports, sports fields, freight yards, slag yards, and environmental - friendly buildings, playing roles such as reinforcement and protection.