Smooth – surfaced Geocel

Short Description:

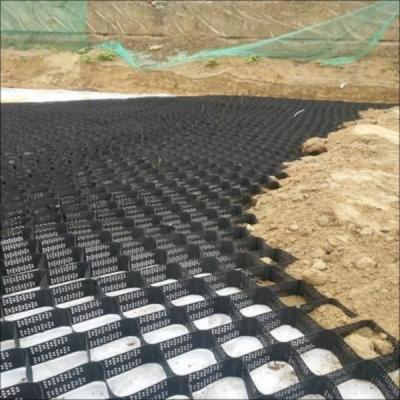

- Definition: A smooth – surfaced geocell is a three – dimensional honeycomb – like reticular geocell structure made of high – strength high – density polyethylene (HDPE) sheets through the extrusion – molding and smooth – surfaced welding process.

- Structural Characteristics: It has a honeycomb – like three – dimensional grid. The walls of the geocell are smooth, without additional patterns or protrusions. This structure gives it good integrity and stability and enables it to effectively confine the filling material.

- Definition: A smooth - surfaced geocell is a three - dimensional honeycomb - like reticular geocell structure made of high - strength high - density polyethylene (HDPE) sheets through the extrusion - molding and smooth - surfaced welding process.

- Structural Characteristics: It has a honeycomb - like three - dimensional grid. The walls of the geocell are smooth, without additional patterns or protrusions. This structure gives it good integrity and stability and enables it to effectively confine the filling material.

Properties

- Physical Properties: It is lightweight, making it easy to handle and construct. It has high tensile strength and tear resistance and can withstand relatively large external forces. It can be freely expanded and contracted. When transported, it can be folded into a small volume to save transportation space. During construction, it can be quickly tensioned into a net - like shape to improve construction efficiency.

- Chemical Properties: It has stable chemical properties, is resistant to photo - oxidative aging, acid - base corrosion, and can maintain stable performance under different soil and environmental conditions and has a long service life.

- Mechanical Properties: It has a strong lateral restraint force. When the geocell is filled with materials such as earth and stone, the walls of the geocell can effectively confine the filler, putting it in a three - directional stress state, thereby greatly improving the bearing capacity of the foundation, reducing roadbed settlement and deformation. It can also evenly distribute the load transmitted from the road surface to a larger area of the foundation soil and effectively reduce the stress on the foundation surface.

Application Areas

- Road Engineering: In sections with weak foundations, laying smooth - surfaced geocell and filling it with suitable materials can form a composite foundation, improve the bearing capacity of the foundation, reduce roadbed settlement and road surface cracking, and extend the service life of the road. It can also be used for slope protection of the roadbed to prevent the slope soil from slipping and collapsing.

- Desert Control and Ecological Restoration: In desert areas, it can be used as the framework of sand - fixation grids. After filling with gravel and other materials, it can fix sand dunes and prevent the movement of wind - blown sand. At the same time, it creates favorable conditions for vegetation growth. Its pores can store water and nutrients and promote seed germination and vegetation rooting.

- Riverbank Protection Engineering: Combined with slope - protection materials, it resists water - flow scouring and protects the riverbank soil from erosion, maintaining the stability and ecological balance of the river course.

- Other Areas: It can also be applied to the foundation treatment of large - scale parking lots, airport runways, wharves and other projects to improve the bearing capacity and stability of the foundation. In some temporary projects, it can also play a role in quick construction and stable support.

Construction Points

- Site Preparation: Before construction, the site needs to be leveled and surface debris, stones, etc. need to be removed to ensure that the foundation surface is flat and solid.

- Geocell Installation: When installing the geocell, it should be carefully spread out and fixed to ensure that it is in close contact with the foundation surface. The connection between adjacent geocells should be firm to ensure the overall stability of the structure.

- Filling Material: The selection of filling materials should be based on the actual needs of the project and the characteristics of the geocell. The filling process should be carried out in an orderly manner to ensure that the filling material is evenly distributed in the geocell and is effectively confined by the geocell.

In Summary

The application technology of geomembrane includes selecting suitable geomembrane, laying geomembrane correctly and maintaining geomembrane regularly. Reasonable application of geomembrane can effectively improve the functions of seepage prevention, isolation and reinforcement of engineering projects, and provide guarantee for the smooth progress of engineering.