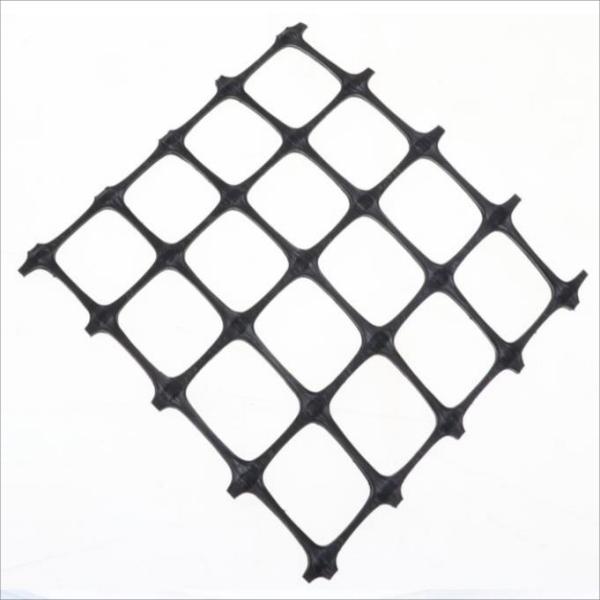

Plastic Geogrid

Short Description:

- It is mainly made of high – molecular polymer materials such as polypropylene (PP) or polyethylene (PE). Visually, it has a grid – like structure. This grid structure is formed through specific manufacturing processes. Generally, the polymer raw material is first made into a plate, and then through processes such as punching and stretching, a geogrid with a regular grid is finally formed. The shape of the grid can be square, rectangular, diamond – shaped, etc. The size of the grid and the thickness of the geogrid vary according to specific engineering requirements and manufacturing standards.

- It is mainly made of high – molecular polymer materials such as polypropylene (PP) or polyethylene (PE). Visually, it has a grid – like structure. This grid structure is formed through specific manufacturing processes. Generally, the polymer raw material is first made into a plate, and then through processes such as punching and stretching, a geogrid with a regular grid is finally formed. The shape of the grid can be square, rectangular, diamond – shaped, etc. The size of the grid and the thickness of the geogrid vary according to specific engineering requirements and manufacturing standards.

Performance Characteristics

1.Mechanical Properties

It has a relatively high tensile strength. The uniaxially - stretched plastic geogrid has particularly outstanding tensile strength in the stretching direction and can withstand large tensile forces without breaking. For example, the tensile strength of some high - quality uniaxially - stretched geogrids can reach more than 100kN per meter, which makes it excellent for reinforcing foundations and preventing lateral displacement of soil.

The biaxially - stretched plastic geogrid has a more balanced biaxial tensile strength and can effectively disperse stress. It can simultaneously exert a restraining effect on the soil in both the longitudinal and transverse directions, enhancing the integrity and stability of the soil mass.

2.Corrosion Resistance

Due to its main components being polymers such as polypropylene or polyethylene, it has good tolerance to chemicals such as acids and alkalis. In some soil environments with high acidity or alkalinity or areas where chemical substances may leak, the plastic geogrid can maintain its own performance stability and will not be damaged due to chemical corrosion, thus ensuring the long - term stability of the project.

3.Abrasion Resistance

Its surface is relatively smooth, but it has a certain abrasion resistance. During the construction process, even if it rubs against soil particles and construction equipment, it will not be easily worn and can ensure the structural integrity and performance of the geogrid are not affected. Moreover, it can also resist the scouring and abrasion of soil particles during long - term use.

4.Drainage Performance

The mesh - like structure of the plastic geogrid is beneficial for drainage. In some foundation treatment projects that require drainage, it can serve as a drainage channel, allowing groundwater or excess water to drain through the pores of the geogrid, reducing the pore - water pressure in the soil and increasing the shear strength of the soil.

Application Areas

1.Road Engineering

It is widely used in the subgrade reinforcement of highways, railways, and other roads. Laying plastic geogrid at the bottom of the subgrade can enhance the bearing capacity of the subgrade and reduce the uneven settlement of the subgrade. Especially in the soft - soil subgrade section, it can effectively disperse the vehicle load transmitted from the road surface, prevent the lateral extrusion of the subgrade soil, and improve the service life and driving comfort of the road.

2.Slope Protection Engineering

It is used for the reinforcement and protection of slopes. By embedding the geogrid into the slope soil, the anti - sliding stability of the soil can be enhanced. The frictional force between it and the soil can prevent the soil from sliding down along the slope surface, and it can also transfer the load at the top of the slope to the interior of the slope body, enabling the slope to remain stable when affected by external factors such as rain - water scouring and earthquakes.

3.Retaining Wall Engineering

Laying plastic geogrid in the backfill behind the retaining wall can reduce the lateral pressure of the backfill on the retaining wall. The interaction between the geogrid and the backfill enables the backfill to form a whole, and part of the lateral pressure of the backfill is converted into the tensile force of the geogrid, thereby reducing the load borne by the retaining wall and lowering the structural size and cost of the retaining wall.