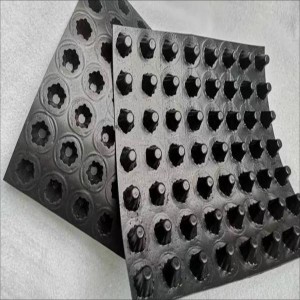

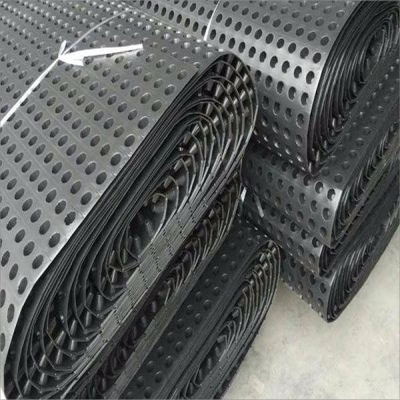

Drainage plate It can not only quickly remove excess water, but also prevent soil erosion and groundwater leakage, which plays an important role in protecting the growth of buildings and plants. However, in the practical application of drainage board, the treatment of joints is very important, which can be related to the drainage effect and the overall stability of the system. So, how should it be connected?

1. The importance of joint connection of drainage board

The joint treatment of drainage board is an important link in the whole drainage system. If the joints are not properly treated, it can cause water to leak through the gaps, and it can also affect the effectiveness of drainage and the life of the system. Therefore, choosing an appropriate joint connection method to ensure the sealing and stability of the joints is crucial for the overall performance of the drainage board system.

2. Connection method of drainage board joints

1、Welding method

The welding method is an efficient and reliable method of joining drainage board joints. Through a professional double weld automatic crawling welding machine, the joints of the drainage board are welded. This method has the advantages of high connection strength, good sealing and strong corrosion resistance. However, before welding, it is necessary to ensure that the surface of the joint of the drainage board is clean, dry and free of debris and oil, so as to ensure the welding quality.

2、Lap joint method

The lap joint method is a simple and easy method of joining drainage board joints. It overlaps the short or long sides of the drainage board and seals it with sealing paste or special adhesive. The overlap length should be reasonably selected according to the specific specifications of the drainage board and the use environment. Generally, the overlap length should not be less than 200 mm。 The lap joint method has the advantages of fast construction speed and low cost, but the sealing effect may be slightly inferior to that of the welding method.

3、Lock connection method

The lock connection method is to connect the lock on the drainage board with the gear bar. When the lock opening of the drainage plate and the notch of the stop bar are completely locked, the fixed connection of the drainage plate can be realized. This method has the advantages of firm connection, simple installation and convenient disassembly. However, the lock and notch between the drain plate and the stop bar must be exactly matched, otherwise a locking connection cannot be achieved.

4、Steel mesh fixing method

The steel mesh fixing method is a joint connection method of drainage board suitable for suspended installation. It places the drain board interface on the reinforced mesh and then fixes it to the mesh with spikes or wire. This method has the advantages of firm fixation and simple installation, but it is suitable for specific scenarios, such as vertical laying of side walls of underground projects.

3. Precautions for joint connection of drainage board

1、Seam treatment needs to be meticulous

When treating the joints of drainage boards, ensure that the joints are smooth and free of debris and oil stains. It is also necessary to choose appropriate sealing materials, such as sealing paste or special adhesive, to ensure the sealing of the joint.

2、The connection strength should be guaranteed

The connection strength of the joints of the drainage board must meet the design requirements to ensure that the drainage system will not leak and deform during long-term use. Therefore, when choosing the connection method, you should consider the specific specifications and usage environment of the drainage board.

3、The construction environment should be suitable

When connecting the joints of drainage boards, ensure that the construction environment is dry, windless and rain-free. In the rainy season or when there is moisture, dew or sediment in the joint, the connection construction cannot be carried out, which will affect the quality of the connection.

As can be seen from the above, there are various connection methods for drainage board joints, and each method has its unique advantages and applicable scenarios. In practical applications, appropriate joint connection methods should be selected according to factors such as specific engineering requirements, drainage board specifications and use environment to ensure the overall performance and stability of the drainage system.

Post time: Jan-14-2025