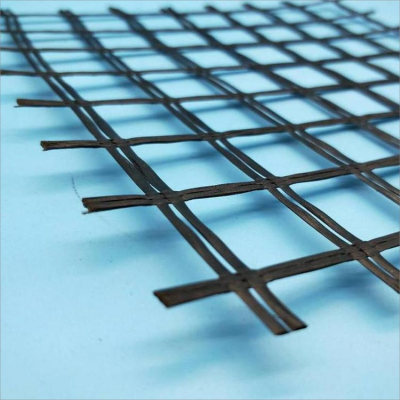

Glass fiber geogrid

Short Description:

Glass fiber geogrid is a kind of geogrid formed by using alkali – free and untwisted glass fiber roving as the main raw material. It is first made into a net – structured material through a special weaving process, and then undergoes surface coating treatment. Glass fiber features high strength, high modulus, and low elongation, providing a good foundation for the mechanical properties of the geogrid.

Glass fiber geogrid is a kind of geogrid formed by using alkali – free and untwisted glass fiber roving as the main raw material. It is first made into a net – structured material through a special weaving process, and then undergoes surface coating treatment. Glass fiber features high strength, high modulus, and low elongation, providing a good foundation for the mechanical properties of the geogrid.

Performance Characteristics

High Strength and High Modulus: It can withstand huge tensile and compressive forces. In road, railway and other projects, it can effectively disperse the load and improve the bearing capacity of the engineering structure.

Corrosion Resistance: It has good resistance to chemical substances such as acids, alkalis and salts. Under different geological and environmental conditions, such as humid and saline-alkali areas, it can still maintain stable performance and is not easy to be corroded and damaged.

Anti-aging: It has excellent ultraviolet resistance and anti-aging ability. Even if it is exposed to the natural environment for a long time, it can still maintain its original mechanical and physical properties, ensuring the long-term stability of the project.

Good Compatibility with Soil: The grid structure is convenient for soil particles to embed, and can form a tight interlocking effect with the soil, so that the soil and the geogrid work together, effectively improving the overall stability and deformation resistance of the soil.

Application Areas

Road Engineering: It is widely used in the construction and repair of roads. When building new roads, it is laid between the subgrade and the pavement, which can enhance the overall strength of the road structure and reduce the occurrence of pavement cracks. In the renovation of old roads, it can effectively suppress the development of reflective cracks, prolong the service life of the road and reduce the maintenance cost.

Railway Engineering: It is used for the reinforcement of railway subgrades, which can improve the bearing capacity of the subgrades, reduce the vibration and settlement generated during the train operation, ensure the smoothness and stability of the railway track, and guarantee the safe operation of the train.

Water Conservancy Engineering: In the construction of water conservancy facilities, such as dams and sluice gates, it can be used to reinforce the soil, prevent slope sliding and collapse, and enhance the stability and safety of water conservancy projects. It can also be applied to the anti-seepage and reinforcement of channels.